Efficient Repair Solutions for Wheel Loader Radiator

Introduction:

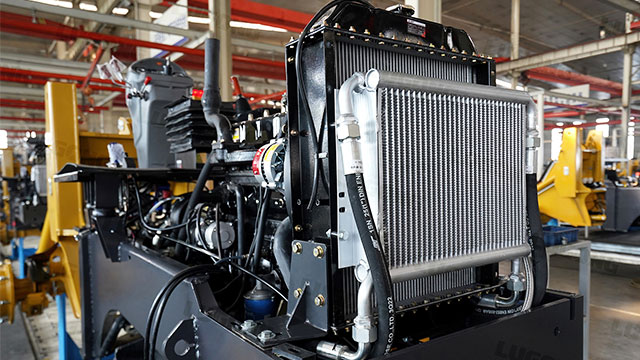

The wheel loader radiator is an essential component of wheel loader, responsible for cooling the engine and preventing overheating. However, due to prolonged usage and harsh working conditions, wheel loader radiators are prone to damage and require regular maintenance and repair. In this article, we will discuss efficient repair solutions for wheel loader radiators, ensuring optimal performance and prolonging the lifespan of this critical component.

1. Diagnostic Assessment:

Before initiating any repair, a thorough diagnostic assessment of the wheel loader radiator is crucial. This assessment should include visual inspection, pressure testing, and thermal imaging to identify leaks, blockages, or any other potential issues. By accurately diagnosing the problem, repair efforts can be targeted efficiently, saving time and resources.

2. Leak Detection and Repair:

Leaks are a common issue in wheel loader radiators, often caused by corrosion, physical damage, or loose connections. Once a leak is detected, it is imperative to repair it promptly to prevent further damage. Repair methods may include patching small leaks with epoxy, soldering, or replacing damaged components. For larger leaks or extensive damage, it is advisable to replace the radiator entirely.

3. Cleaning and Flushing:

Over time, radiators accumulate debris, sediment, and rust particles that can obstruct the cooling system’s efficiency. Regular cleaning and flushing of the radiator are essential to maintain optimal performance. This process involves removing the radiator from the wheel loader, disassembling it, and using specialized cleaning agents or solutions to remove dirt and debris. Flushing the radiator with water or a chemical cleaner can help eliminate any remaining contaminants.

4. Core Replacement:

In severe cases where the radiator core is damaged beyond repair, a core replacement may be necessary. The core is the heart of the radiator, responsible for heat exchange. Replacing the core involves removing the damaged core and installing a new one. It is crucial to ensure the replacement core matches the specifications of the wheel loader radiator to maintain compatibility and efficiency.

5. Regular Maintenance:

Prevention is always better than cure. Regular maintenance of the wheel loader radiator is key to avoiding major repair issues. Maintenance practices may include inspecting for leaks, checking coolant levels, ensuring proper airflow, and cleaning radiator fins. Additionally, it is important to follow the manufacturer’s recommended maintenance schedule, which may involve replacing coolant, hoses, and clamps periodically.

Conclusion:

By conducting a thorough diagnostic assessment, promptly addressing leaks, cleaning and flushing the radiator, replacing damaged cores when necessary, and implementing regular maintenance practices, operators can ensure the radiator operates at its best. Remember, a well-maintained radiator will not only enhance the performance of the wheel loader but also prevent costly downtime and repairs.