What are the main parts involved in compact wheel loader?

Introduction to Compact Wheel Loaders:

Compact wheel loaders are versatile and powerful machines commonly used in construction, agriculture, and landscaping projects. Understanding the main parts involved in a compact wheel loader is essential for efficient operation and maintenance. Let’s delve into the key components that make up this impressive piece of compact wheel loader.

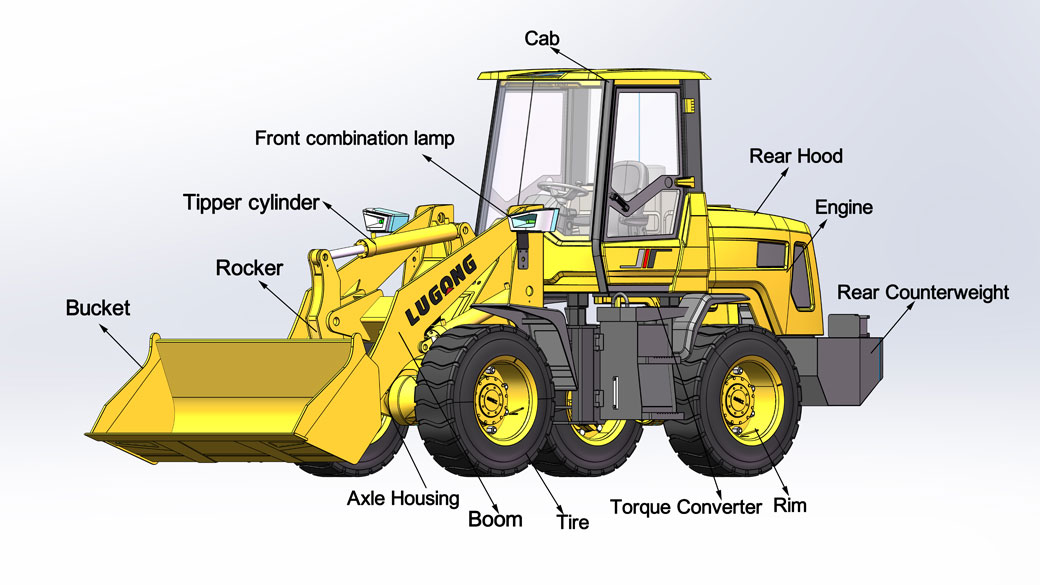

1. Chassis: The chassis serves as the framework of the compact wheel loader, providing stability and structural support. It is designed to withstand heavy loads and rugged terrains while maintaining balance and maneuverability.

2. Engine System: The engine is the heart of the compact wheel loader, providing the necessary power to operate the machine. Compact wheel loaders often feature diesel engines, known for their durability and fuel efficiency. The engine’s horsepower determines the compact wheel loader’s lifting capacity and speed.

3. Transmission: The transmission system transfers power from the engine to the wheels, enabling the compact wheel loader to move forward and backward. It allows for smooth shifting between gears, ensuring optimal performance and control.

4. Loader Arms and Bucket: The loader arms, also known as lift arms or booms, are attached to the front of the compact wheel loader and provide the lifting mechanism. They are responsible for raising and lowering the bucket attachment. The bucket, typically made of durable steel, is used for scooping, lifting, and dumping materials such as soil, gravel, or debris.

5. Hydraulic System: Enabling Efficient Operations. The hydraulic system plays a crucial role in the operation of a compact wheel loader. It uses hydraulic fluid to transmit power, allowing for precise control of the machine’s movements. The hydraulic system powers the loader arms, bucket, steering, and other attachments.

6. Steering System: The steering system enables the operator to control the direction of the compact wheel loader. Common steering systems include articulated and skid steering. Articulated steering provides excellent maneuverability by allowing the machine to bend in the middle, while skid steering offers tight turning capabilities by independently controlling the speed and direction of each wheel.

7. Operator Cab: The operator cab is the compartment where the operator sits and controls the compact wheel loader. It is designed to provide comfort, safety, and visibility. Modern cabs often feature ergonomic seating, climate control, and advanced control panels for ease of operation.

8. Tires: Compact wheel loaders are equipped with large, rugged tires designed to provide traction and stability on various terrains. The tires may be filled with foam or air to further enhance compact wheel loader stability and load-bearing capacity.

In conclusion, a compact wheel loader consists of several essential parts that work together to achieve efficient and reliable performance. Understanding these components is crucial for operators and technicians to ensure proper maintenance and safe operation. With their versatility and power, compact wheel loaders continue to be valuable assets in various industries.