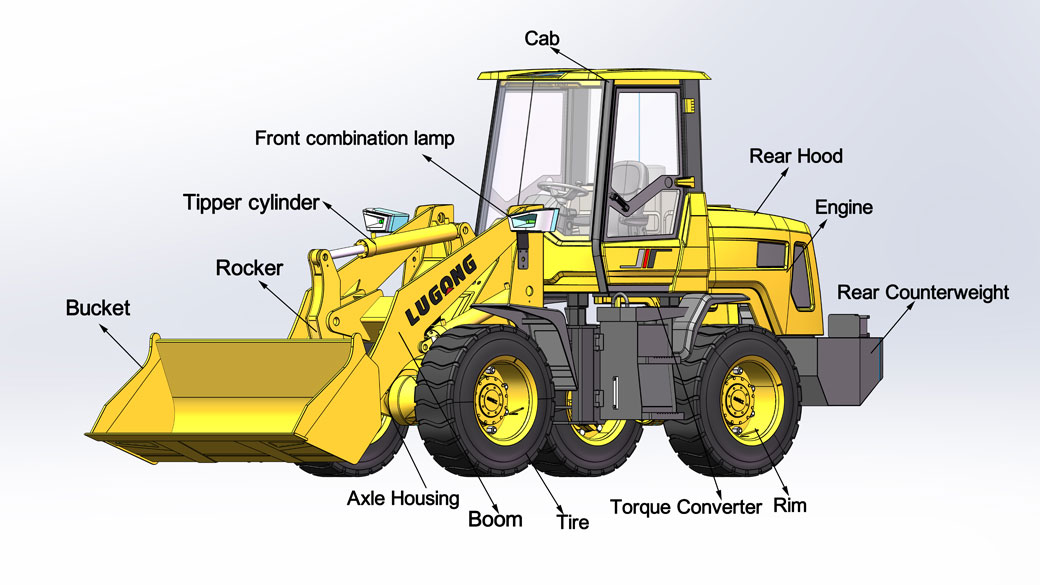

What parts of the wheel loader may need to be regularly maintained?

Wheel Loader Maintenance Introduction:

A wheel loader is a heavy equipment machine commonly used in construction and mining industries for various tasks such as loading, transporting, and dumping materials. To ensure the efficient and safe operation of a wheel loader, regular maintenance is essential. This article will discuss the key parts of a wheel loader that require regular maintenance to keep the machine in optimal working condition.

1. Engine Maintenance:

The engine is the heart of a wheel loader and requires regular maintenance to ensure its smooth functioning. Regular oil changes, air filter replacements, and fuel filter replacements, and inspections of belts, hoses, and cooling systems are crucial. It is also important to check and maintain proper coolant levels and ensure the radiator is clean and free from debris. Proper lubrication of engine components is also necessary to prevent excessive wear and tear.

2. Hydraulic System Maintenance:

The hydraulic system in a wheel loader is responsible for powering various functions, such as lifting and dumping materials. Regular inspection of hydraulic hoses, seals, and fittings is necessary to identify any leaks or damages. Adequate hydraulic fluid levels and filter replacements are vital for the efficient operation of the wheel loader’s hydraulic system. Greasing all the pivot points and moving parts of the hydraulic system should also be done regularly.

3. Transmission and Drivetrain Maintenance:

The transmission and drivetrain components of a wheel loader need regular maintenance to prevent breakdowns and ensure smooth operation. Regularly checking and changing transmission fluid, inspecting drive belts, and lubricating drive shafts and axles are essential tasks. Any unusual noises, vibrations, or leaks should be promptly addressed.

4. Tire Maintenance:

The tires of a wheel loader are subjected to heavy loads and rough terrains, leading to wear and tear. Regular inspection for tire pressure, tread depth, and any signs of damage or excessive wear is crucial. Proper tire inflation and rotation should be done to maximize tire life and ensure optimal traction and stability.

5. Brake System Maintenance:

The brake system of a wheel loader is critical for the safety of both the operator and the surrounding environment. Regular inspections of brake pads, discs, and lines are necessary to ensure the wheel loader proper functioning. Checking brake fluid levels, brake pads, and rotors should be part of routine maintenance. Any signs of brake fluid leaks, unusual noises, or reduced braking performance should be addressed immediately to ensure safe operation.

6. Electrical System Maintenance:

The electrical system of a wheel loader controls various functions, including lights, gauges, and controls. Regular inspection of wiring, connectors, and batteries is necessary. Cleaning and tightening connections, replacing faulty components, and ensuring proper battery charging are essential for the reliable operation of the electrical system. Regularly checking and maintaining the battery, alternator, and starter motor is also important to avoid unexpected breakdowns.

Wheel Loader Maintenance Conclusion:

Regular maintenance of a wheel loader is essential to ensure its optimal performance, minimize downtime, and extend its lifespan. By regularly maintaining the engine, hydraulic system, tires, braking system, and electrical system, operators can maximize the efficiency and safety of the wheel loader. Neglecting maintenance can lead to costly repairs, reduced productivity, and safety hazards. Therefore, it is crucial to follow a comprehensive maintenance schedule provided by the manufacturer and address any issues promptly.