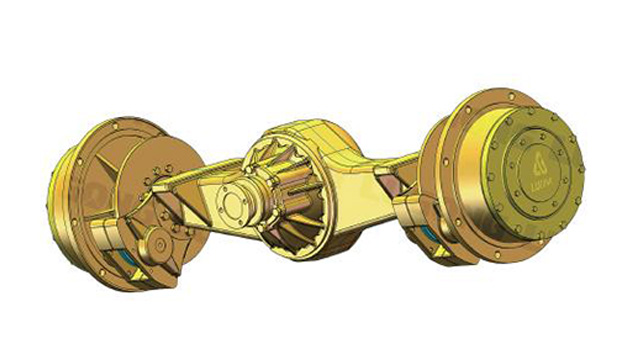

Wheel Loader Parts-Introduction to Drive Axle

Wheel loader is heavy equipment machine used in the construction sector. The drive axle is an important part of the wheel loader. Knowing the drive axle can help you better understand and drive a wheel loader.

The working principle of the drive axle

The transaxle is the mechanism at the end of the driveline that changes the rotational speed and torque from the transmission and transmits them to the drive wheels. The drive axle is generally composed of the main reducer, the differential, the wheel transmission device and the drive axle housing, etc. The steering drive axle also has a constant velocity joint. The transaxle is also subjected to vertical, longitudinal and lateral forces, as well as braking moments and reaction forces acting between the road surface and the frame or body.

Drive axle function

The drive axle is located at the end of the power train, in order to transmit the engine torque from the universal transmission device to the driving wheels through the main reducer, differential, half shaft, etc., so as to reduce the speed and increase the torque; through the main deceleration The bevel gear pair changes the direction of torque transmission; the differential effect of the wheels on both sides is realized through the differential to ensure that the inner and outer wheels turn at different speeds; the bearing and torque transmission are realized through the axle housing and the wheels.

Design requirements for drive axles

The final reduction ratio should be selected to ensure the best power and fuel economy of the vehicle.

The external dimensions should be small to ensure the necessary ground clearance. Mainly refers to the size of the main reducer as small as possible. Gears and other transmission parts work stably with low noise. High transmission efficiency at various speeds and loads. Under the condition of ensuring sufficient strength and stiffness, the mass should be small, especially the unsprung mass should be as small as possible to improve the ride comfort of the vehicle. Coordinate with the movement of the suspension guide mechanism, and for the steering drive axle, it should also be coordinated with the movement of the steering mechanism. The structure is simple, the processing technology is good, the manufacture is easy, and the disassembly, assembly and adjustment are convenient.